Latest News: FuturEnergy signs contract with WF Recycle-Tech to deliver 1.5T/hr commercial tyre pyrolysis plant

Biochar CleanTech Accelerator - Sustainability Innovator Of The Year ‘Highly Commended’ winners at Innovation Awards 2025

Latest News: FuturEnergy signs contract with WF Recycle-Tech to deliver 1.5T/hr commercial tyre pyrolysis plant Biochar CleanTech Accelerator - Sustainability Innovator Of The Year ‘Highly Commended’ winners at Innovation Awards 2025

Decarbonise construction materials with PyroFlex products

Converting Residual Biomass into Construction Inputs

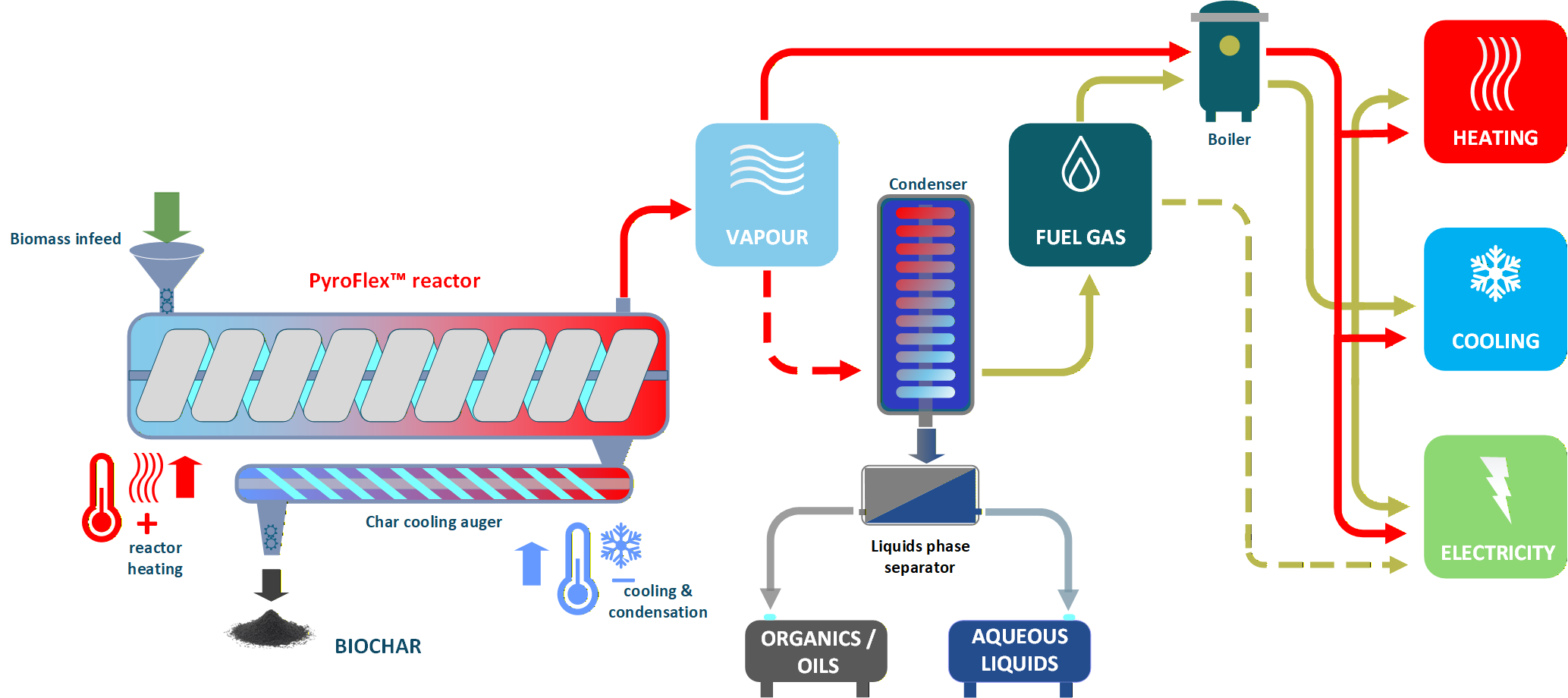

The construction materials industry increasingly faces pressure to reduce embodied carbon while maintaining cost, performance, and supply reliability. PyroFlex enables producers of cement, concrete, aggregates, bricks, panels, and timber-based products to convert residual biomass - such as wood waste and process residues - into energy and low-carbon products.

Biochar as a Low-Carbon Construction Material Input

Biochar produced by PyroFlex offers several promising applications within the construction materials sector. In concrete and cementitious products, biochar can be used as a partial cement or filler replacement, supporting reductions in embodied carbon while contributing to improved material efficiency, depending on formulation and standards compliance. Biochar also shows potential in lightweight aggregates, insulating materials, panels, renders, and asphalt applications, where its carbon stability and physical properties can be beneficial when appropriately engineered.

Low-Carbon Energy for Energy-Intensive Processes

PyroFlex provides dispatchable, low-carbon heat, cooling, and electricity, well suited to the energy-intensive nature of construction materials manufacturing. This energy can be used for cement and lime processing support, aggregate drying, kiln operations, curing chambers, space heating, and on-site power demand. By displacing fossil fuels, PyroFlex helps reduce Scope 1 emissions while improving energy resilience and shielding operations from energy price volatility.

Carbon Storage Within the Built Environment

When incorporated into construction materials, biochar offers the opportunity for long-term carbon storage within the built environment, effectively locking biogenic carbon into infrastructure for decades. This creates a pathway for construction projects to move beyond emissions reduction toward carbon storage and potential carbon-negative outcomes, subject to verification and accepted accounting frameworks. For developers and materials producers, this strengthens ESG credentials and supports compliance with increasingly stringent embodied carbon reporting requirements.

Supporting Decarbonisation and Regulatory Compliance

By combining low-carbon energy generation with biochar utilisation, PyroFlex helps construction materials producers address both operational emissions and embodied carbon. The use of biogenic feedstocks, fossil fuel displacement, and stable carbon storage supports measurable lifecycle emissions reductions, aligning with net-zero roadmaps, green building standards, and sustainable procurement frameworks increasingly demanded by clients and regulators.

Reduced Waste and Improved Circularity

PyroFlex supports a circular economy approach within construction by converting biomass waste streams into energy and material inputs that can be used within local supply chains. This reduces landfill dependency, minimises transport emissions, and improves overall material efficiency - key priorities for construction companies operating under waste reduction and circularity targets.

A platform to access existing and emerging markets

As low-carbon construction materials evolve, PyroFlex provides a flexible, future-ready platform. Output priorities can shift between energy, biochar, and liquid products as standards, markets, and carbon accounting frameworks develop. This flexibility allows construction materials producers to adopt PyroFlex as both a near-term decarbonisation solution and a long-term strategic asset.