Latest News: FuturEnergy signs contract with WF Recycle-Tech to deliver 1.5T/hr commercial tyre pyrolysis plant

Biochar CleanTech Accelerator - Sustainability Innovator Of The Year ‘Highly Commended’ winners at Innovation Awards 2025

Latest News: FuturEnergy signs contract with WF Recycle-Tech to deliver 1.5T/hr commercial tyre pyrolysis plant Biochar CleanTech Accelerator - Sustainability Innovator Of The Year ‘Highly Commended’ winners at Innovation Awards 2025

Generate heating, cooling and electricity from your biomass

Flexible Carbon-Negative Energy with PyroFlex

PyroFlex provides clients a flexible, future-proof way to produce energy that aligns with both commercial and decarbonisation objectives.

By converting low-value biomass residues and waste streams into a controllable, low-carbon energy source, PyroFlex allows sites to generate energy in the form of heating, cooling, or electricity - or a combination of all three - directly where it is needed. This on-site energy production reduces exposure to volatile energy prices, improves energy security, and enables better use of waste streams.

Engineered for Decarbonisation

PyroFlex is designed to materially reduce lifecycle carbon emissions. When operated on sustainable biomass or biogenic residues, the energy produced is classed as low-carbon or renewable, helping clients lower their Scope 1 and Scope 2 emissions.

In addition, the process can generate stable carbon-rich co-products that support carbon sequestration pathways, further strengthening ESG performance. This makes PyroFlex particularly attractive for organisations under pressure to meet net-zero targets, comply with tightening carbon regulations, or demonstrate credible progress on sustainability - without compromising on reliable energy supply.

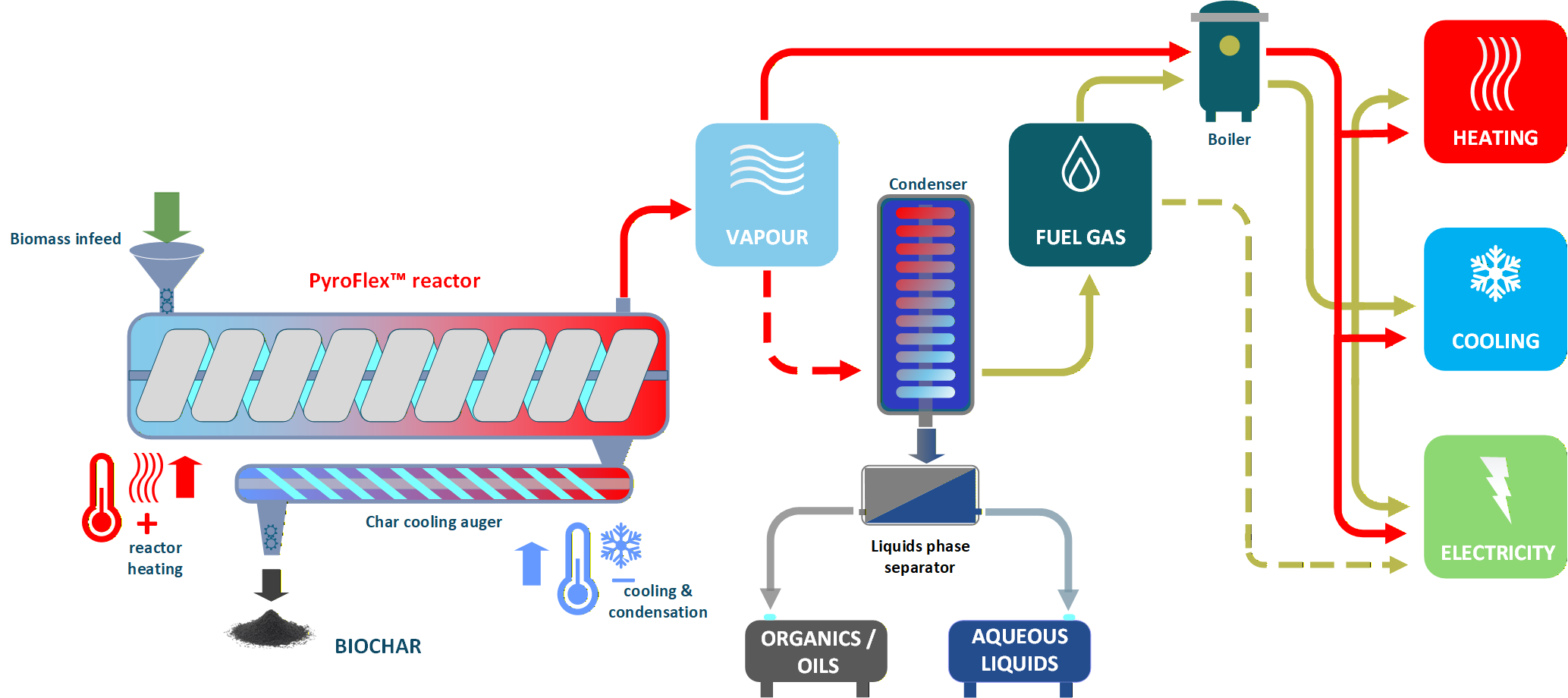

PyroFlex Pyrolysis System Process Flow

This diagram shows the PyroFlex™ process and its two configurable product options. Biomass is converted in the PyroFlex reactor into biochar and a hot process vapour. The solid red lines represent PyroFlex Vapour, where this vapour is used directly for heating, cooling, or electricity generation. The solid green lines show PyroFlex Condenser, where additional equipment condenses the vapour into organic oils and aqueous liquids, with the remaining fuel gas recovered for energy use.

PyroFlex energy outputs are deployed across multiple sectors

Dispatchable low-carbon heat and power are used for grain drying, greenhouse heating, food processing, and on-farm energy demand, reducing reliance on fossil fuels and improving energy cost stability.

On-site energy is used for kiln drying, space heating, process heat, and electrical demand, enabling sawmills to convert residues into reliable energy while improving operational efficiency and resilience.

Low-carbon heat and power support cement and lime processing, aggregate drying, curing chambers, and manufacturing operations, directly reducing Scope 1 emissions in energy-intensive processes.

Energy outputs are used to supply public buildings, depots, leisure centres, district heating networks, and EV infrastructure, delivering local, controllable energy aligned with net-zero strategies.