Latest News: FuturEnergy signs contract with WF Recycle-Tech to deliver 1.5T/hr commercial tyre pyrolysis plant

Biochar CleanTech Accelerator - Sustainability Innovator Of The Year ‘Highly Commended’ winners at Innovation Awards 2025

Latest News: FuturEnergy signs contract with WF Recycle-Tech to deliver 1.5T/hr commercial tyre pyrolysis plant Biochar CleanTech Accelerator - Sustainability Innovator Of The Year ‘Highly Commended’ winners at Innovation Awards 2025

Extract valuable liquid products from your biomass

Profit from processing your residual organic materials

PyroFlex extracts biogenic liquid products from residual biomass including an organic oil phase and an aqueous phase, enabling clients to produce lower-carbon alternatives to fossil-derived inputs.

The aqueous phase contains a range of water-soluble organic compounds that make it suitable for controlled-use applications such as herbicides and fungicides, wood preservation, and selected industrial chemical processes, subject to formulation, regulatory approval, and end-use validation.

Enter emerging markets - displacing chemical products

In addition, the aqueous phase shows potential for plant growth, soil conditioning, and nutrient efficiency applications, where it may partially offset conventional chemical fertiliser inputs in specific use cases. These applications are classified as emerging markets, requiring further field trials, regulatory clearance, and site-specific performance assessment.

When combined with biochar production - returned to land for long-term carbon sequestration - PyroFlex supports both low-carbon product substitution and permanent carbon removal, helping clients demonstrate credible lifecycle emissions reductions without overstating performance claims.

Soil Conditioning

Plant Growth Stimulant

Partial Fertiliser Displacement

Soil Biology Support

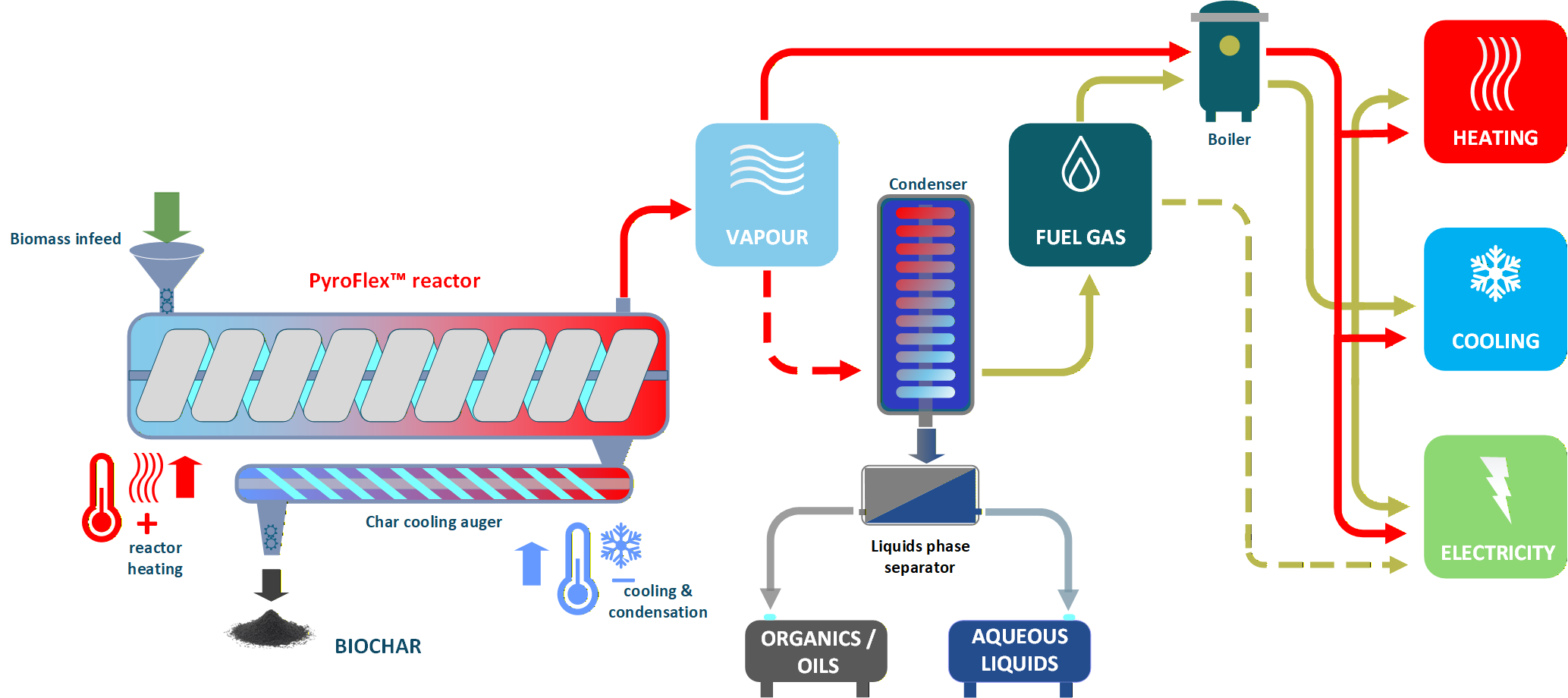

PyroFlex Pyrolysis System Process Flow

This diagram shows the PyroFlex™ process and its two configurable product options. Biomass is converted in the PyroFlex reactor into biochar and a hot process vapour. The solid red lines represent PyroFlex Vapour, where this vapour is used directly for heating, cooling, or electricity generation. The solid green lines show PyroFlex Condenser, where additional equipment condenses the vapour into organic oils and aqueous liquids, with the remaining fuel gas recovered for energy use.

PyroFlex liquid outputs are deployed across multiple sectors

Pyrolysis liquids can be evaluated for soil conditioners, biostimulants, or agricultural inputs, subject to formulation, regulation, and application-specific testing.

Liquids may be utilised as process additives or energy carriers within industrial operations, depending on site requirements and downstream processing pathways.

Pyrolysis liquids are assessed for use in binders, additives, and low-carbon material formulations, supporting innovation in sustainable construction products.

Liquids are primarily used within demonstrator projects and innovation programmes, supporting research, validation, and future commercial pathways for low-carbon materials and products.