Latest News: FuturEnergy signs contract with WF Recycle-Tech to deliver 1.5T/hr commercial tyre pyrolysis plant

Biochar CleanTech Accelerator - Sustainability Innovator Of The Year ‘Highly Commended’ winners at Innovation Awards 2025

Latest News: FuturEnergy signs contract with WF Recycle-Tech to deliver 1.5T/hr commercial tyre pyrolysis plant Biochar CleanTech Accelerator - Sustainability Innovator Of The Year ‘Highly Commended’ winners at Innovation Awards 2025

Convert sawmill residues into commercially valuable products

Turning Sawmill Residues into Value

Sawmills generate large volumes of residual biomass—including bark, sawdust, chips, fines, and off-cuts—that are often sold at low value, transported off-site, or disposed of at cost.

PyroFlex enables sawmills to convert these residues into valuable products on site, transforming the unavoidable by-product of timber processing into a strategic asset. By upgrading biomass internally, mills can reduce handling costs, improve margins, and increase overall resource efficiency.

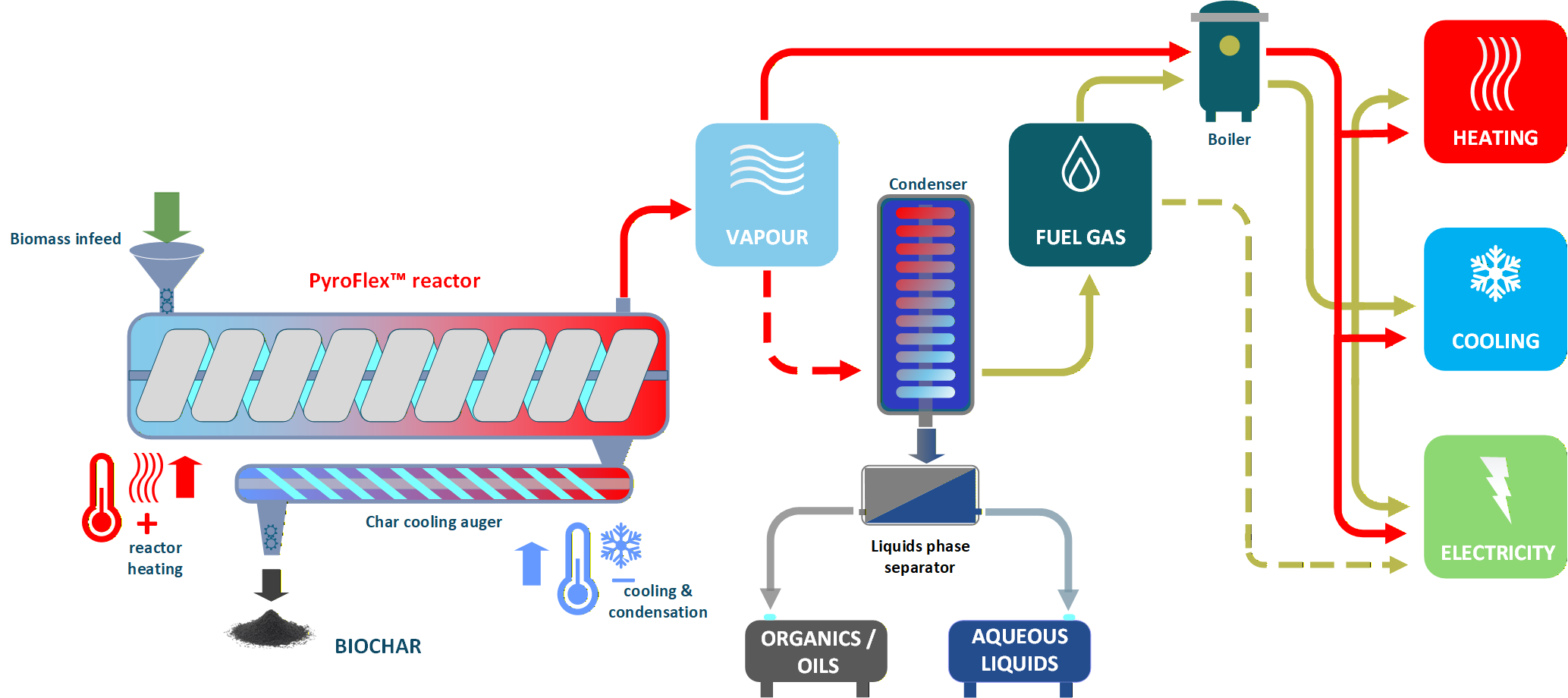

On-Site Energy for Heating, Cooling, Drying, and Power

PyroFlex provides sawmills with low-carbon thermal energy, cooling, or electricity directly from their own residues. This energy can be used for kiln drying, space heating, process heat, or site power demand - reducing reliance on fossil fuels and exposure to volatile energy prices. Unlike intermittent renewables, PyroFlex provides dispatchable, controllable energy, aligned with continuous industrial operations and seasonal throughput variations typical of sawmill sites.

Producing Low-Carbon Liquid Products

In addition to energy, PyroFlex has the option to produce biogenic liquid products, including an organic oil phase and an aqueous phase, creating further value streams from sawmill residues. These liquids can be used as low-carbon fuel substitutes, chemical feedstocks, or industrial intermediates, subject to application-specific requirements. For sawmills, this opens pathways beyond energy generation, allowing participation in emerging low-carbon materials and chemical markets.

Biochar and Carbon Sequestration Opportunities

PyroFlex separates and stabilises a portion of the biomass carbon into biochar, which can be returned to land for long-term carbon sequestration. For sawmills with forestry or land management links, this creates a closed-loop opportunity—returning carbon to soils while improving soil health and resilience. Biochar use also strengthens sustainability credentials and may support future participation in carbon credit or inset schemes, subject to verification and market rules.

Decarbonisation and ESG Benefits

By converting biogenic residues into useful energy and products, PyroFlex helps sawmills achieve measurable lifecycle emissions reductions. The displacement of fossil fuels lowers Scope 1 emissions, while the production of low-carbon products and permanent carbon storage strengthens Scope 3 and ESG performance. This positions PyroFlex as a practical decarbonisation solution for mills facing increasing pressure from customers, regulators, and financiers to demonstrate credible progress toward net-zero targets.

Reduced Logistics and Improved Site Efficiency

On-site processing with PyroFlex reduces the need to transport bulky, low-value residues off-site, lowering haulage costs, traffic movements, and associated emissions. This simplifies site logistics and improves operational resilience, particularly for remote or high-throughput sawmills where residue management can be a constraint on production.

A platform to access existing and emerging markets

PyroFlex is designed as a flexible platform, allowing sawmills to adapt outputs over time as markets, regulation, and energy pricing evolve. Whether prioritising energy self-sufficiency, liquid product offtake, or carbon outcomes, PyroFlex enables mills to respond to future opportunities without locking into a single use case—future-proofing residue management strategies in a rapidly changing regulatory and commercial landscape.